AGRARIAN, ENGINEERING AND MATERIAL SCIENCES

Industrial design in the light of science

Professional at the CONICET conducts photometric trials to assess the quality of different light sources.

Nowadays, it is unthinkable to imagine our life without the comfort that offers electric light by pushing a button or turning a knob. In spite of that simplicity, it is essential to make a rational use of it. All kinds of lights, including the smallest bulbs, the lights in stadiums or on the streets, are all studied in detail to guarantee their energetic efficiency.

In order to improve their performance, the devices are analysed through photometric trials that show how they distribute light and therefore the characteristics of clarity in the surfaces they illuminate. At the Laboratorio de Fotometría del Instituto de Investigación en Luz, Ambiente y Visión (ILAV, CONICET-UNT) [Laboratory of Photometry of the Research Institute for Light, Environment and Vision] of Tucumán, and the Departamento de Luminotecnia, Luz y Visión (FACET-UNT) [Department of Lightning, Light and Vision], Federico Buriek, principal professional at the CONICET, is responsible for conducting these studies focused on the needs manufacturers have to certify the characteristics of their products and have the photometric curves of use in outdoors and indoors lightning.

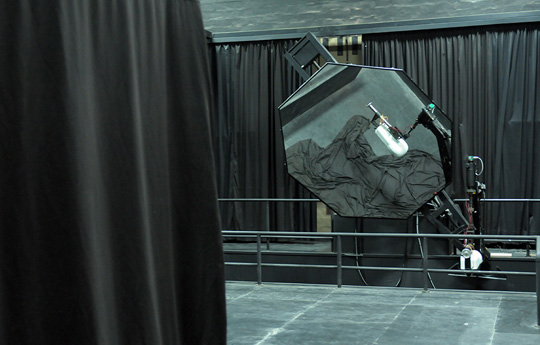

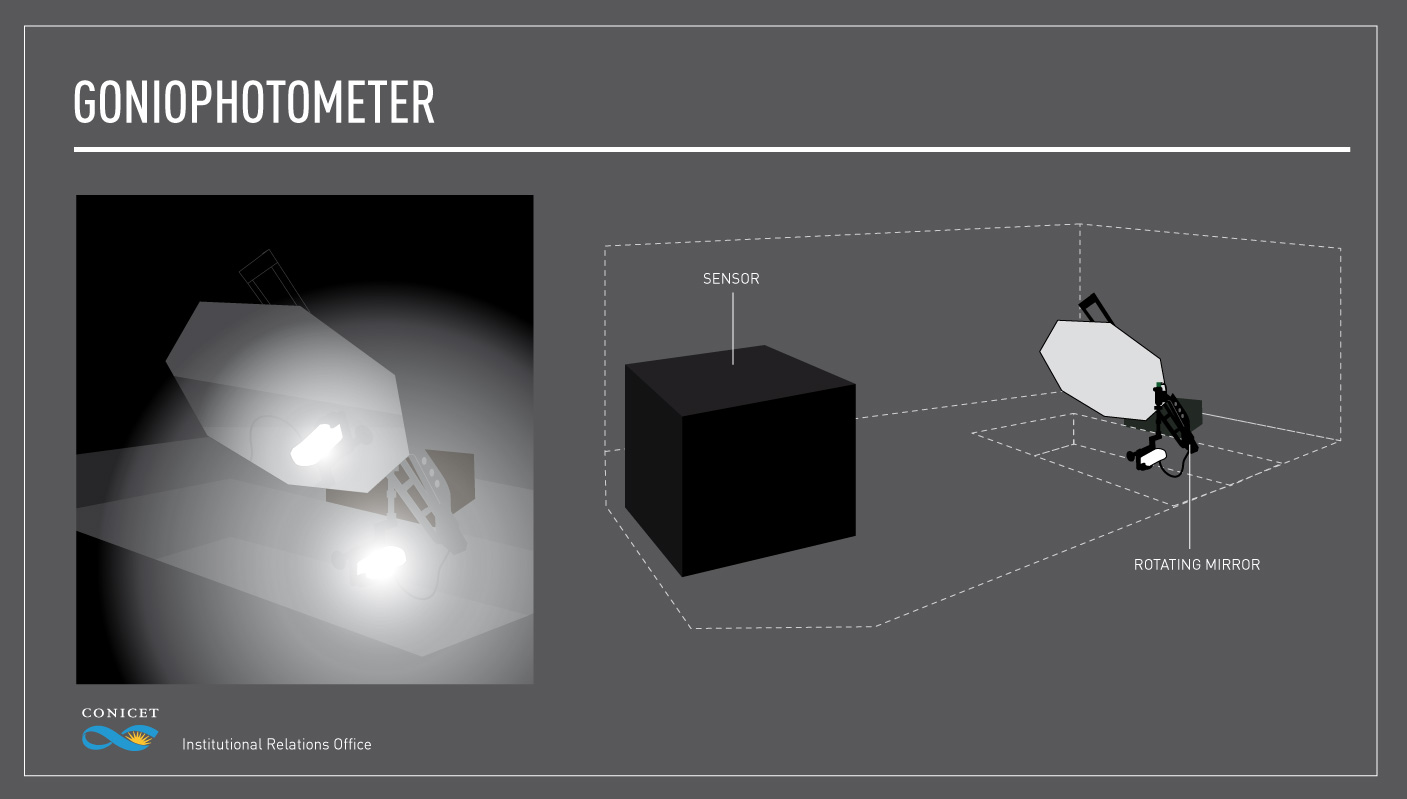

“At the laboratory we conduct trials for research projects and services to third parties. We measure the luminous intensity of the sources of light as well as the lights used to illuminate the streets and the lamps or devices used inside an office, for instance. In a device called goniophotometer, we put the source and this device. By combining the rotation of the mirror and the arm, it measures the amount of light emitted at different angles a sensor reaches”, the principal researcher explains.

The electronic engineer states that the arm where the device to be measured is located rotates 360° at a relatively slow pace. The combination of the movement of the mirror and the arm, together with a fixed sensor that always points to the centre of the mirror to capture the device from every angle, allows the professionals to record the information that at the end of the trial shows how the light of source is distributed in all directions. This distribution and light output data is used by manufacturers to produce the optical design of luminaires and also by designers for calculations of lightning projects.

The goniophotometer with rotating mirror has operated since 1979 and was one of the first in the world. In South America, it served as a model for others installed in the region. It can characterize sources of light of linear dimensions of up to 2 metres and 60 kilograms.

Finally, Buriek comments that each device needs a special assembly to be adapted to the goniophotometer, and this task is also conducted by ILAV professional at a workshop in which they also preserve the luminaire samples analysed from the moment the goniophotometer began to operate in the laboratory.

“Working in the laboratory is interesting because we can have direct contact with the latest technologies and trends used in lightning”, he concludes.

- By Cecilia Leone.